The value of DIF

The Digital Innovation Facility is home to six state-of-the-art and most advanced development laboratories in Europe.

Our facilities represent six uniquely grouped leading-edge digital tools and equipment.

Our facilities represent six uniquely grouped leading-edge digital tools and equipment.

A space dedicated to ensuring your Artificial Intelligence (AI) systems are reliable, safe and secure.

From smart cities to smart factories, improving efficiencies, safety, and predictability. Low-cost sensors and connected devices have become ever-present in the modern world. The data these devices capture, process and communicate are increasingly becoming critical threads in the autonomous tapestry of our society.

From point of care, clinical diagnostics to medical imagery, AI algorithms and autonomous systems will be the engines that power the next big leap in healthcare. Our facilities boast clinical and engineering networks to help democratise the potential of AI and big data for inclusive healthcare.

Self-driving cars, boats, submarines, and industrial machinery; the laboratory provides the hardware and infrastructure necessary to evaluate and verify the algorithms driving your autonomy to perform as planned without fail.

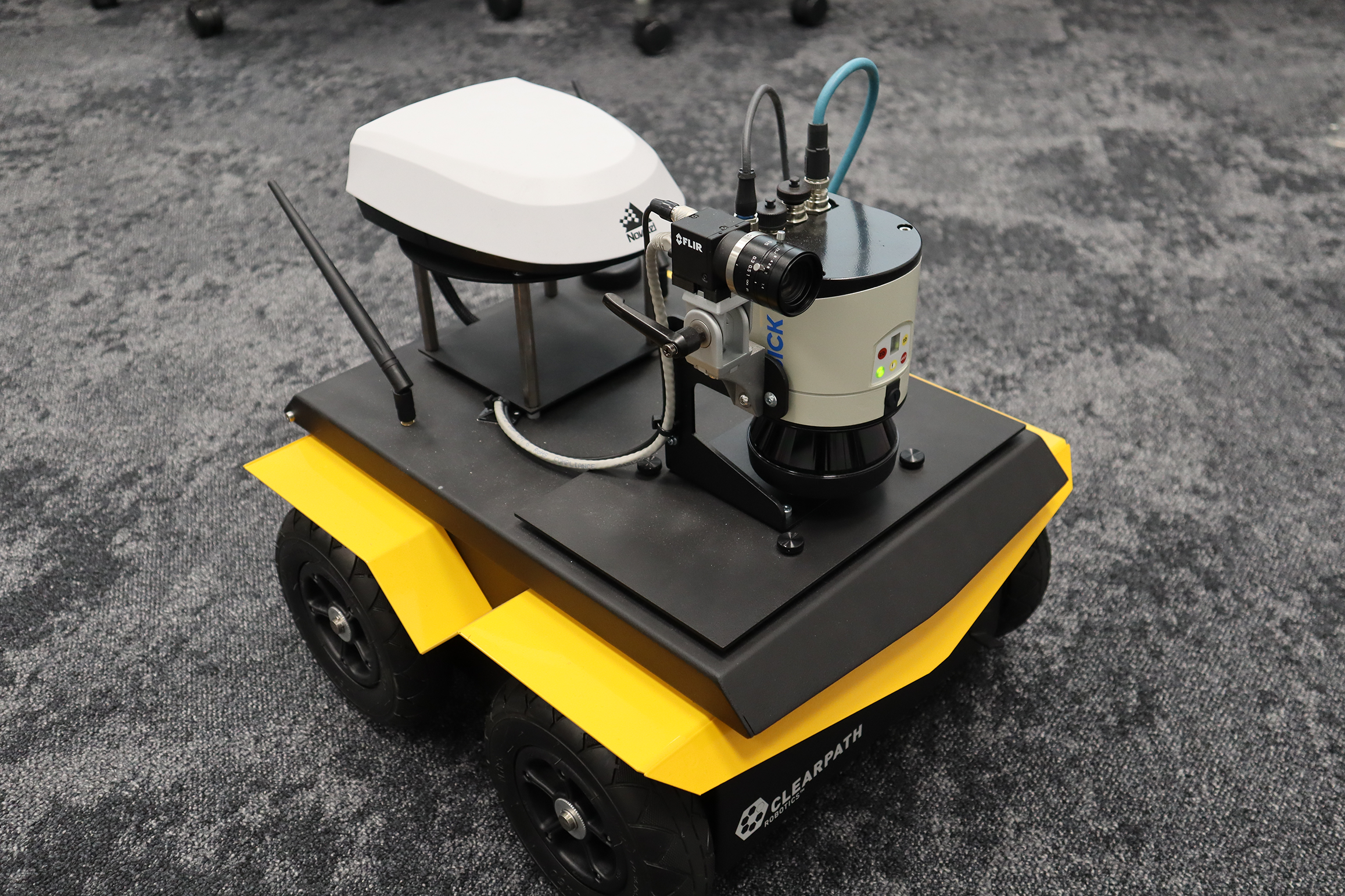

Jackal Explorer

Jackal Explorer robot; a small, fast, entry-level field robotics research platform. It has an onboard computer, GPS and IMU whilst being fully-integrated with ROS for out-of-the-box autonomous capability. Jackal is a plug-and-play device, compatible with a huge list of robotic accessories for quickly applying to any industrial application.

Turtlebot Waffle Pi

A pack of Turtlebot Waffle Pi robots can provide an ideal adaptable platform for the low-cost evaluation and development of multiple applications for environment mapping and multi-agent and swarm deployment.

Pro UAV’s

A fleet of professional and pro-consumer UAV’s for the development and testing of algorithms for aerial application. From autonomous flight for patrol and survey, to fault detection and tracking from the air.

From aerial surveys of renewable energy infrastructures like offshore wind farms to autonomous deployment for search and rescue drones, UAV’s are becoming an increasingly important asset for sectors including utilities and infrastructure to environmental conservation and first responders.

DIF’s laboratories go further than simply testing whether a drone can stay on course in a crosswind, the facility tests both the hardware and the software driving it. Our capability evaluates the algorithms, sensors, software, and communication platforms that safe and effective operations are built upon.

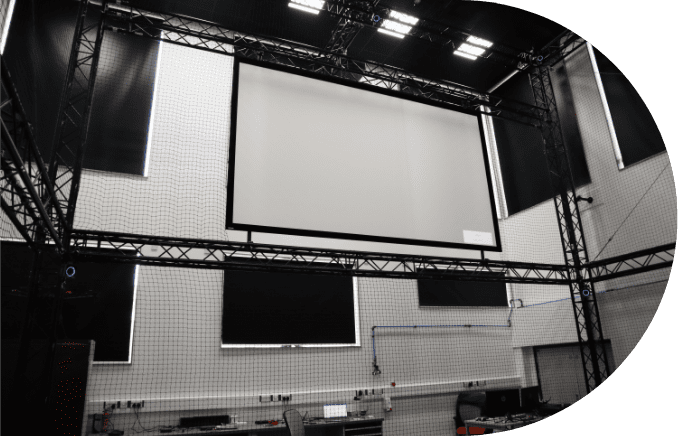

The laboratory enjoys a uniquely reconfigurable design that allows complex industrial structures to be set up under controlled conditions. This allows both robotic systems and their component’s ability to deal with realistic scenarios to be fully investigated and assessed.

Floor tether points to support the creation of industrial landscapes

State-of-the-Art Motion Capture System to track robot movements

Wind Generator to create ‘harsh atmospheric environmental conditions’

Medium projection system to simulate system environments

The latest UAV’s from 3DR, DJI and Dr. Robot

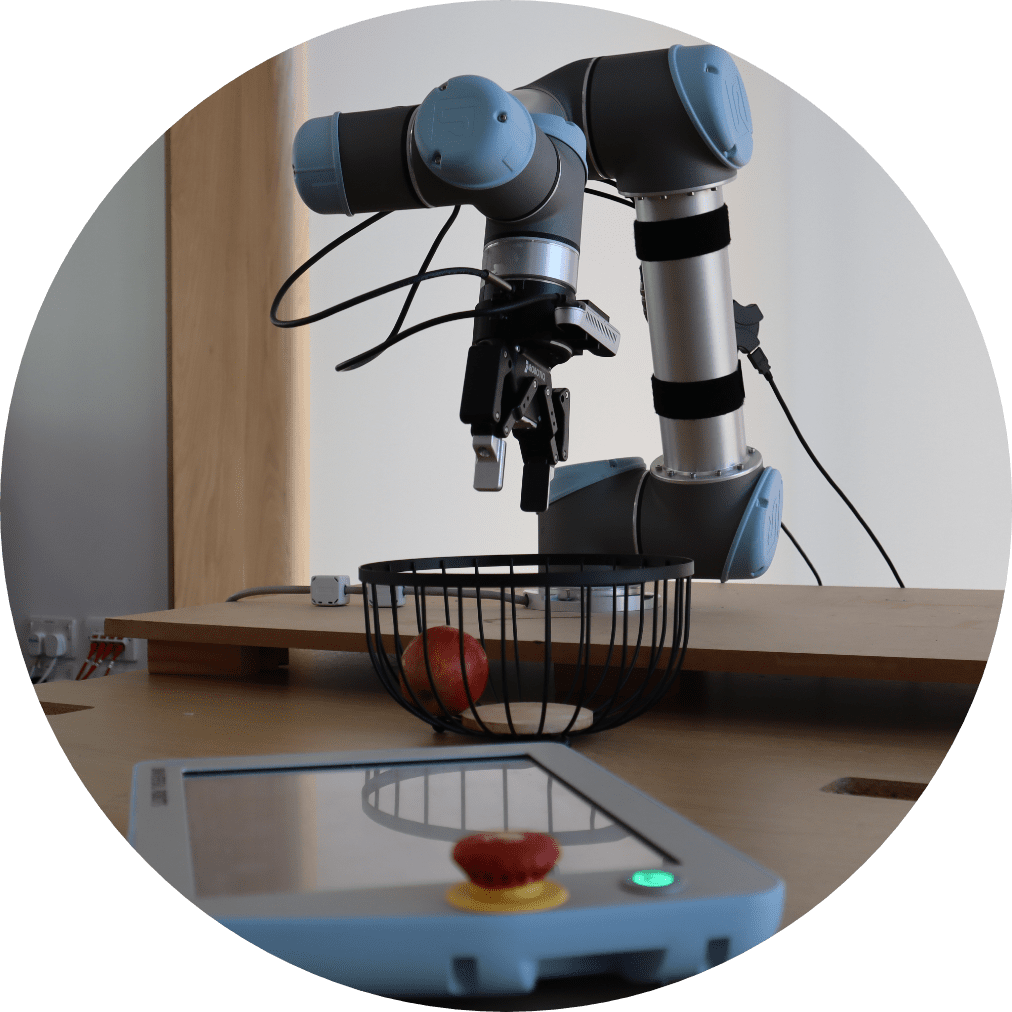

The DIF’s smARTLab is focused on advancing the development and testing the application of sensing and perception technologies needed to enable robots to safely and reliability perform delicate and complex tasks.

From robotic surgery to precision manufacturing, one of the biggest challenges is developing robotic systems that can learn to perform accurate operations with delicate materials in dynamic and uncontrolled environments. This facility focuses on enhancing the vision and tactile sensing and learning of robots.

Industrial partners can benefit from both applied expertise and R&D to help advance new robotic installations as well as enhance existing and legacy infrastructures.

The smARTLab is a 13,843 ft³ test arena that can deliver a range of innovation support to de-risk and accelerate product assessment & testing in sectors including:

Manufacturing

Medical Robotics

Laboratory automation

Utilities and Infrastructure

The latest UAV’s from 3DR, DJI and Dr. Robot

The laboratory hosts multiple collaborative robotic arms from industrial vendors including Universal Robotics, ABB, Robotiq and KUKA. The team are also experienced in developing sensing applications for a variety of robotic product platforms from Turtlebot, Parrott and CrazyFlie.

Accelerating autonomous robotic chemistry.

The DIF is leading the application of autonomous robotics & AI to deliver the Laboratory of the Future. Building on the capabilities of the Leverhulme Research Centre for Functional Materials Design, the team pair the latest advancement in AI-driven chemistry.

Home to the UK’s leading laboratory for developing Autonomous Chemistry, the Leverhulme Research Centre for Functional Materials Design is led by Professor Andy Cooper and Dr Ben Alstom.

The team have expertise within laboratory robotics, creating the “Lab of the Future”, a self-driving autonomous scientific laboratory powered by artificial intelligence and robotics. The laboratory is to developing a scalable robotics platforms for multi-use robotic chemists.

This physical capability of rapidly adaptable physical assets is paired with custom-designed automated workflows to provide a step-change in the use of automation for chemistry and materials science environments.

The Autonomous Chemistry Laboratory is composed of a dual-arm collaborative robot from ABB, KUKA and Franka Emika Panda. The lab has the capability for multiple mobile assets capable of complex tasks and manipulation alongside more conventional high-throughput laboratory equipment.

Our vision is to create a system to accelerate materials discovery driven by artificial intelligence: not just imitate scientific actors, but to create robotics, based upon scientific discoverers.

The team’s most advanced work is in the field of Olfaction & Gustation, paving the way for the transmission of smells and tastes across the Internet.

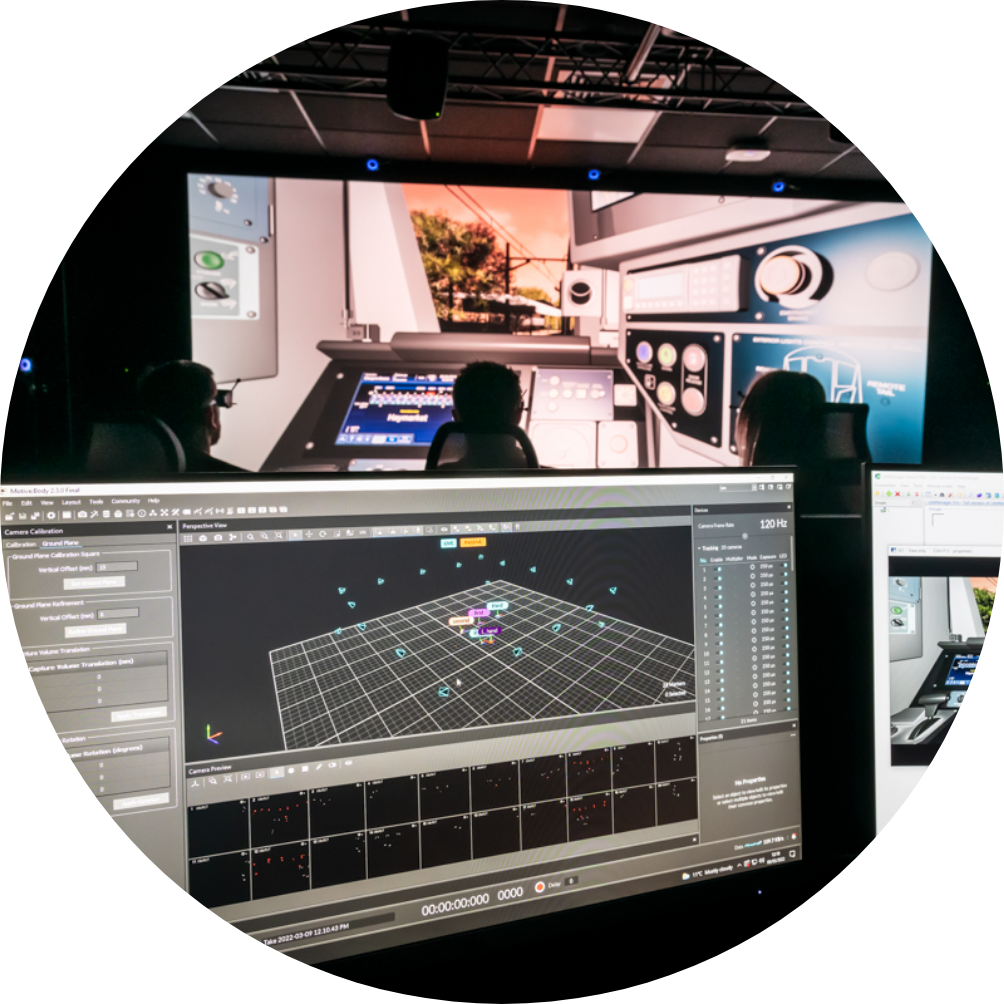

The Immersive Laboratory provides a unique facility for partners looking to advance the human experience in immersive environments, from retailers looking to give Internet users a chance to “feel” a product online, to healthcare companies and advanced manufacturing businesses wanting to add a greater depth of fidelity and dimension to training simulations and remote operations.

This new capability makes the space ideal for collaborative design, object interaction, design reviews or multi-person working. Teams can individually interact with their virtual model within the same physical location while still being able to see each other’s non-verbal behaviour such as gestures and proxemics enabling more natural user interactions while working. Moreover, with the use of avatars for user representation, solutions can be networked to enable remote experts to join the session.

Images are displayed across a 5 x 2.5m screen in native 4k resolution at a refresh rate of 360Hz, the screen is powered by three high end graphic workstations capable of real-time raytracing, offering our partners a more crisp and realistic experience.

The Mixed Reality Laboratory also features a large tracked space where physical objects can be located to enhance the simulation experience. Participant and object tracking will be represented in high-fidelity with sub-millimetre accuracy with the capability to capture whole body motion of individuals and represent this in real-time and immersive simulations.

Within the MR Lab, Powerwall visualisations can be enhanced with the addition of data layers that can be interacted with via a dashboard on a 4K touch screen display. Allowing stakeholders and decision makers to identify trends, highlight problems and predict future implications of decisions in an intuitive way.

Furthermore, the lab is equipped with an array of Virtual and Augmented Reality head mounted displays for individual or networked experiences, 4k touch screens for visualisation and interaction, and scanning technologies to allow the accurate capture and visualisation of existing environments or objects.

Activities within the Mixed Reality Laboratory focus on the solution of real-world industrial problems across all industry sectors, with particular emphasis on the realisation of complex high-fidelity digital twins and testbeds for industrial systems and processes. The experienced MR Lab team consists of visualisation professionals, developers and human factors experts who can not only create virtual experiences, but also validate them.